PolyOne Helps Global Vision 2020 Bring the USee™ to Life

April 8, 2019

A Pioneering Vision Correction Solution for the Developing World

Global Vision 2020 is a nonprofit on a mission to bring better vision to the 2.5 billion people across the globe who currently have no access to eye care. It’s biggest challenge? Creating a diagnostic device that can be used to determine a person’s eyeglass prescription without the support of a doctor or vision specialist. PolyOne proudly accepted this challenge and collaborated with the nonprofit's founder, Kevin White, to design a simple and effective device specially designed for use in under-resourced communities. Since clinical trials began in 2016, this approach has delivered correct-strength glasses to approximately 36,000 people in 38 countries.

Designers Brian Everett, Jane Spikowski, and John Church of PolyOne’s IQ Design team donated design time and expertise to help White, executive director of GV2020, develop his invention, a diagnostic device called the U-See™. Together, the PolyOne team worked on industrial design, ergonomics, manufacturability, and material selection for the device, together with White and toolmaker/molder Alpha Tool and Mold, a longtime PolyOne customer.

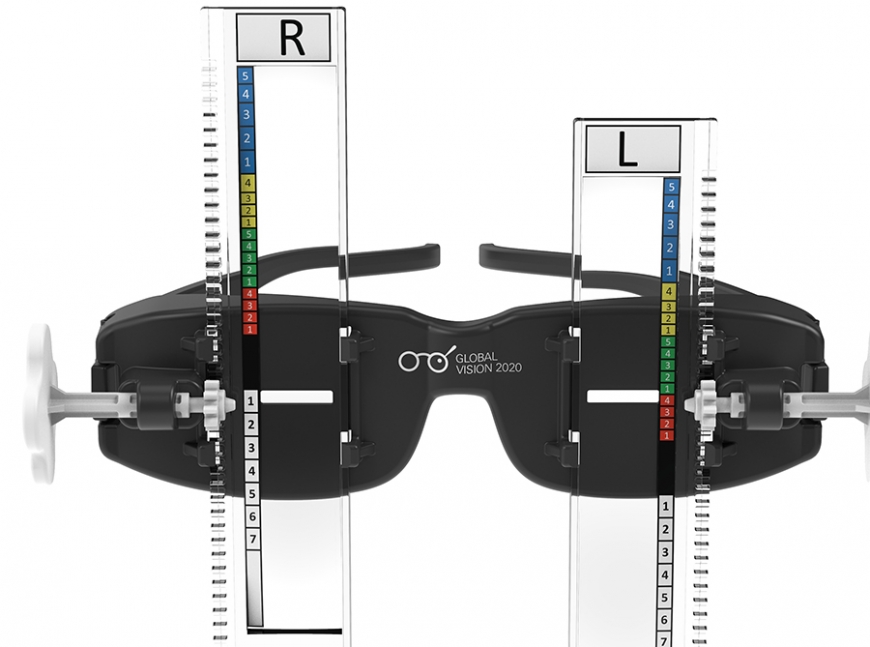

This device enables local volunteers trained as ‘refractionists’ to assist patients, who turn dials on the USee to determine their own prescription (self-refraction). Volunteers then make a pair of snap-together, correct-strength eyeglasses on site. GV2020 calls it the “Dial-Snap-Wear” method, and it takes about 15 minutes per person. The USee device is packaged within a kit that contains various strength lenses and conventional eyeglass frames.

“I first started working on this problem more than 14 years ago when on international missions in the Marine Corps,” said Kevin White, executive director, Global Vision 2020 and inventor of the USee device. “Why did I choose this particular issue? Because if left uncorrected, poor vision hinders education, limits prospects for employment, causes vehicular accidents, and prevents individuals from attaining personal independence and prosperity. Clear sight is truly a life changing gift.”

“Working towards a solution to a world problem of this scale is in perfect alignment with PolyOne’s sustainability goals and commitment to our communities, both local and global,” said Cathy Dodd, Vice President, Marketing at PolyOne. “Through our design expertise, deep material science resources, and the energy and passion of our associates, PolyOne is well placed to help organizations such as GV2020 achieve their goals and make the world a better place to live.”

VIDEO NOTE: PolyOne has created a video detailing this collaboration, which can be viewed here: A Pioneering Vision Correction Solution for the Developing World

About PolyOne

PolyOne Corporation, with 2018 revenues of $3.5 billion, is a premier provider of specialized polymer materials, services and solutions. The company is dedicated to serving customers in diverse industries around the globe, by creating value through collaboration, innovation and an unwavering commitment to excellence. Guided by its Core Values, Sustainability Promise and No Surprises PledgeSM, PolyOne is committed to its customers, employees, communities and shareholders through ethical, sustainable and fiscally responsible principles. For more information, visit www.polyone.com.

About Global Vision 2020

Global Vision 2020 is an IRS 501(c)(3) registered charity and is committed to delivering clear vision to 2.5 billion people in remote, poverty-stricken parts of the world. It is a mission, a passion, a moral imperative. For more information, visit www.gv2020.org.

About Alpha Tool and Mold

Alpha Tool and Mold, located in Highland Heights, Ohio, has been serving the plastic molding and die cast industries since 1978, specializing in building precision plastic injection molds, including hot runner and unscrewing types, die cast dies, and related components. Additional capabilities include precision machining and prototype work for various industries, plastic custom molding for both sampling and production runs, and engineering support for tool design optimization. For more information, visit https://www.alphatoolandmold.com.

# # #

PHOTO CAPTION: PolyOne’s IQ Design team assisted with the design, moldfilling analysis, and production of the injection-molded USee device, which includes a copolyester frame, medical-grade polycarbonate lenses, and acetal for the dials and gears.

EDITORS: For high-resolution images, please click here: FOR MEDIA USE ONLY

To access PolyOne’s news library online, please go to www.polyone.com/news

Media contact

Michelle Maniscalco

Senior Manager, Marketing Communications

PolyOne Corporation

+1 440-930-1988

michelle.maniscalco@avient.com

Press Resources

Investor News

Avient To Hold Fourth Quarter 2025 Conference Call... More

Avient Announces Third Quarter 2025 Results... More

Avient Announces Fifteenth Consecutive Annual Dividend Increase... More